Product Design Engineering School of Design

Ross McFadyen

Stitch – Modular Footwear that is Designed to Change

Modern shoes feature complicated constructions made of synthetic materials and cements, making them almost impossible to repair or dispose of sustainably. We are all guilty of buying more than we need, and disposing of them prematurely, with 24 billion pairs of trainers ending up in landfill every year, most of which will never biodegrade.

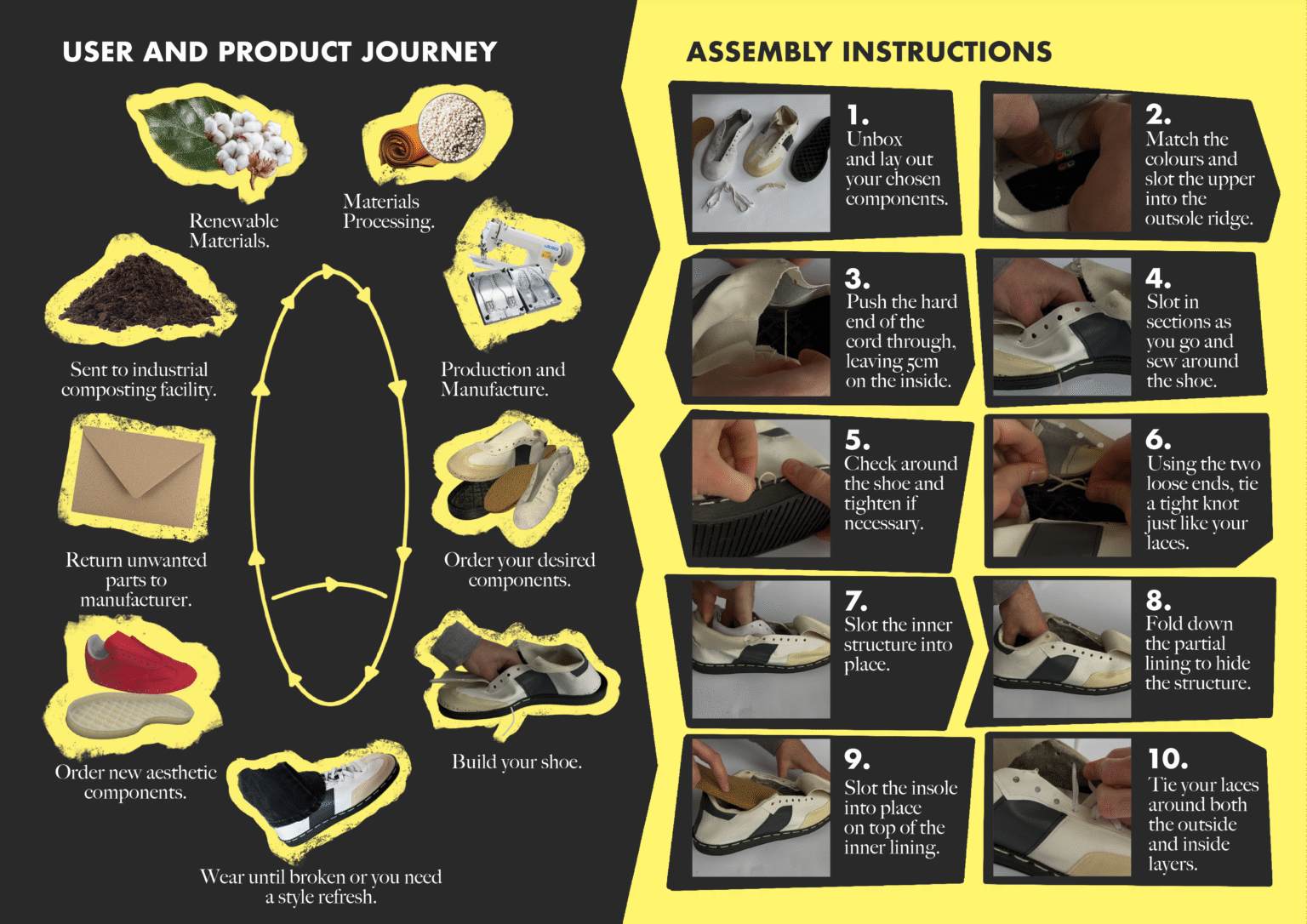

Stitch is designed as an alternative to the current footwear model, featuring a simplified construction made of only six components that can be disassembled and assembled entirely by hand, by stitching around the shoe. It is for anyone who wants to do things a little differently, whether that is someone who wants to express themselves in a more unique way, reduce their environmental impact or even just keep up with the latest trends for less. The discrete and versatile attachment method allows for a wide range of options for consumers, incentivising them to shop more sustainably.

A carefully selected palette of natural materials and biopolymers allows for Stitch to be entirely compostable in an industrial environment. This allows users to send back unwanted parts which can then be returned to the earth, creating a truly circular system.